Rock testing – sample selection

To minimize the error during the testing procedure, the proper selection of samples is crucial depending on the type of test to be performed.

According to the purpose of the test, the samples can be obtained from diamond core-drilled boreholes, or from boulders taken from blasting activities or rock falls (not recommended for strength parameters determination).

When sending core-drilled samples, SMCOY suggests the following points for a more efficient testing procedure.

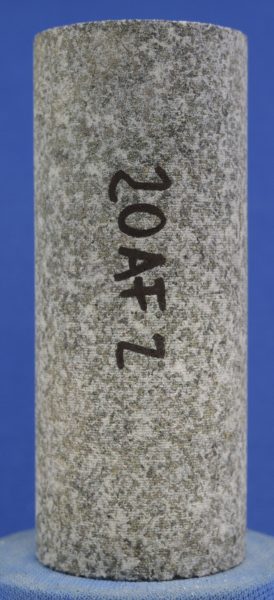

Diamond drill core examplesDiamond drill core samples recommendations

Dimensions

For tests to determine the strength of the rock (UCS, TCS, BTS), the ISRM recommends core-drilled samples of minimum 50 mm in diameter, and a length of approximately two times (2x) the diameter. Therefore, long core drill samples are recommended so after sawing the testing samples fulfill this requirement.

(UCS, TCS, BTS), the ISRM recommends core-drilled samples of minimum 50 mm in diameter, and a length of approximately two times (2x) the diameter. Therefore, long core drill samples are recommended so after sawing the testing samples fulfill this requirement.

Sampling size

The diameter of the sample should be preferably ten times (10x) the average grain size so individual crystals do not distort the test result. This is seldomly the case for crystalline rock, therefore needs to be compensated with a larger number of samples.

A minimum of 3 tested samples per rock type is advised, being 5 the recommended value. The more heterogeneous the rock type, the larger the sample size necessary to reduce the scatter. The mean and its scatter are usually settled by 5 to 10 samples per rock type.

During the preparation works at the laboratory the samples are generally sawed to the ISRM specifications length and the flat parallel ends are grinded to micro-metric accuracy to ensure a proper compression test. These processes are conducted under the most careful conditions; nevertheless, the sample might break along weaknesses present on the surface. Taking this in consideration, it is a good practice to add one or two spare samples per rock type to be tested.

Sample selection – general recommendations

When choosing the samples to be shipped, is a good practice to bear in mind the foliation of the samples.

The compressive strength of the rock is usually the lowest when loaded at an angle of 30 – 60 degrees regarding the foliation orientation. In the same sense, the highest compressive strength is found when loaded against or parallel to this orientation. The compressibility of the foliated rocks, the coefficient of elasticity, is the lowest perpendicular to the foliation, and the highest parallel to it.

On the other hand, the tensile strength of a rock sample is the lowest perpendicular to foliation, usually.

Shipping

When shipping the samples to the laboratory, the samples must be properly packed. It is recommended the drill cores to be wrapped in bubble wrap and placed in a drill core box of appropriate size. These precautions will help to avoid breakage during transportation.

When testing porous and weak stones, special care must be taken to retain the original rock moisture. The rock samples to be tested must be packed in a moisture-proof manner as soon as obtained, since dried weak porous rocks will break very easily during transportation and preparation.

Identification

For a proper reporting, the correct identification of the samples to be tested is essential. We encourage our clients to pre-fill the following sample list and send it to us via email when shipping the samples.

The list contains the client’s sample names, borehole ID from where it was taken, geological unit investigated, client’s naming convention, and test to be performed. This minimizes errors when reporting similar rock types and provides a better control of the results for both parts.

Boulder samples

No drill cores are required for drillability and abrasivity index testing. In contrast, rock samples from boulders of sufficient size are enough to perform the tests.

Additionally, strength tests (UCS, TCS, BTS) can be performed on cores extracted from boulders*. The core drilling of the boulders can be done at the laboratory at extra cost. The only requirement in this case is that the boulder is big enough to have the ISRM recommended dimensions.

*Not recommended for sensitive infrastructure projects.