Borehole stress measurements

Overcoring stress measurement

SMCOY has developed a new fully mechanical overcoring cell based on the same principle as the LVDT cell. The device can be used using the wireline system and will measure stresses accurately.

The DDP36 probe is a robust device design to measure the horizontal stress state in 36 mm vertical boreholes (overcoring >76 mm).

Hydraulic fracturing stress measurement

SMCOY uses Mini Frac Hydraulic fracturing equipment (Mindata Ltd) for in situ stress measurements with hydraulic fracturing technique. The current range for hole diameters for hydraulic fracturing measurements are 38, 46 or 56 mm.

SMCOY uses Mini Frac Hydraulic fracturing equipment (Mindata Ltd) for in situ stress measurements with hydraulic fracturing technique. The current range for hole diameters for hydraulic fracturing measurements are 38, 46 or 56 mm.

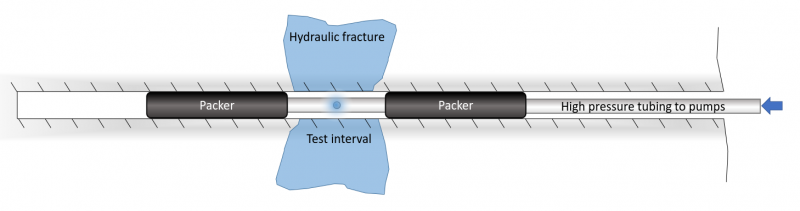

In the hydraulic fracturing (HF) stress measurement an inflatable double packer system is used to seal a test section in a borehole. The test section is preferably located in primary stress state, where no interferences from tunnel are present. The test section is pressurized using water and the water pressure is increased until a new rock fracture is induced. Usually 2 MPa higher pressure is used in packers than the test section in order to seal the test section properly and to prevent leaking through the packers. Also in the classic HF measurement the test section must locate in intact rock. A schematic illustration of the hydrofracturing tool is presented below.